Specific Introduction

Xinyuan C70W is a hydraulic excavator walking with 8 wheels.

As a wheel backhoe, in the C70W, there is a powerful hydraulic system, sturdy and dependable structural elements, a large and comfortable cab, a quick and easy maintenance technique, and it is attractive. This entire machine flies its own colors with its high working performance, high working rate, high stability, superior comfort, large convenience, and beautiful look.

Major vital ydraulic excavator parts are listed below for your reference.

The Engine: With the support of a high-pressure common rail injection system, the engine for this new kind can deliver powerful power while being environmentally friendly and compliant with China's National Emission Regulations for Non-road Machinery. This novel load-sensing hydraulic system is designed to accurately manage and then deliver the required power based on the machine's loading situation. When compared to a standard hydraulic system, using this type of system and engine will save more fuel and reduce the heat generated by the system itself.

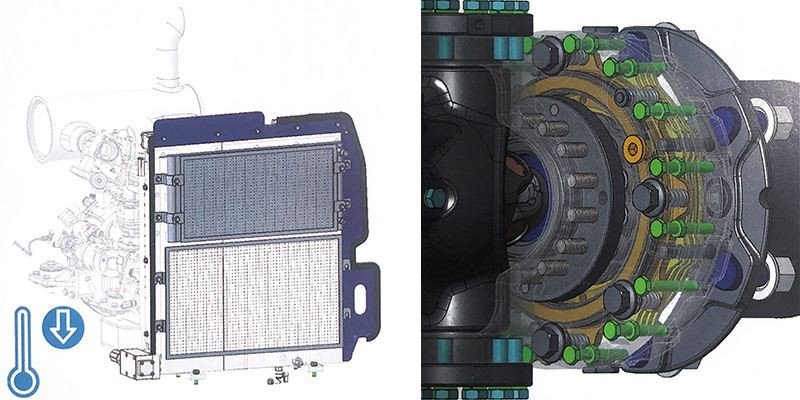

The Radiator and Barking System: The combined radiator has an intercooler. A larger cooling compartment aids in the cooling of heat generated by the motor and hydraulic system, resulting in improved performance. There are two independent sets of barking tubes in the dual hydraulic wheel wet braking system, as the name suggests. The brake sealing design is more secure. The four-wheel independent wheel side brake provides increased stability and better stopping performance. Parts with a full life cycle design, consistent quality, easy maintenance, and less stress.

Front and Rear Axle: Reinforced front and rear drive axle with high-strength axle housing, stronger bearing capacity, owns a number of patents. The axle is equipped with automatic transmission, strengthened internal gear and mechanical parking brake, which is safer than others.

The Vehicle Body: the vehicle is equipped with an upper platform with better resistance and boom side layout. We optimize the internal structure so that all working devices can work with high intensity. All cast iron integrated rear counterweight block and embracing low center of gravity structure make our machine firm and reliable.

Driving Space: The cab's internal structure is more roomy, and the large-size glass design allows for a larger field of vision and a smaller blind area. At the bottom, there is a damping plate design that not only improves comfort but also improves sound insulation. The cab's working devices are laid out in an ergonomic manner, and automated gear shifting makes the driver's job easier. Each small excavation comes standard with a complete vehicle instrument intelligent control system, as well as a new operation panel. High-definition reverse views and blind area monitoring are also available. functions.

The Surface of Vehicle:The maintenance project layout is uniform and windowed, and the body cover may be opened in a big area. The user only needs to gently pull the switch to complete the daily maintenance in one step. Inside the machine, there is also a high-capacity toolbox, which is more handy for users.

Modular System:

The excavator becomes a multi-functional working equipment thanks to the modular rapid changeover technology. A variety of devices that are suited for a variety of working circumstances and are meant to increase the product's longevity and productivity.

Controlling System: In the whole machine, there are intelligent parts such as the intelligent controlling system, dashboard assembly, operating plate assembly, monitor video, main controller, front-middle-back body controller, and other intelligent parts. Furthermore, the CPU will sound an alert if the machine breaks down or stops working for up to 800 different reasons. As a result, the user will be aware of them and will be able to have them properly fixed in a timely manner.

Walking Device: The C70 tires are unique construction machinery tires that provide stability and safety when walking and operating. The machine's application scope may be expanded and the advantages maximized thanks to its efficient and adaptable walking construction.

Technical Data

| DIMENSIONS | |

| Overall Length | 5775mm |

| Overall Width | 2010mm |

| Overall Height | 2845mm |

| Spread of Axles | 2456mm |

| Tyre Type | 825-16 |

| Width of Grounding | 500mm |

| Track | 1595mm |

| Min Height Above Ground | 285mm |

| Width of Bulldozing | 2070mm |

| Rising Distance of Bulldozing | 470mm |

| Height of Bulldozing | 50mm |

| Width of Bucket | 700mm |

| RANGE OF OPERATION | |

| Max Digging Reach | 6520mm |

| Max Digging Depth | 3630mm |

| Max Digging Height | 6335mm |

| Max Dumping Height | 4720mm |

| Min Front Radius | 2345mm |

| Min Tail Radius | 1655mm |

| TECHNICAL SPECIFICATION | |

| Engine | YUCHAI 4F30 |

| Power/Speed | 48kw/2200rpm |

| Machine Weight | 6665kg |

| Volume of Bucket | 0.25-0.40m³ |

| Set Pressure of Main Overflow Valve | 24MPa |

| Max Digging Force | 40kN |

| Gradeability | 35° |

| Max Traction Force | 40kN |

| Max Travel Speed | 30km/h |

| Swing Speed of Platform | 10.5rpm |

| Fuel Tank Capacity | 140L |

| Hydraulic Tank Capacity | 120L |